BUSINESS

- HOME

- BUSINESS

- Software

Software

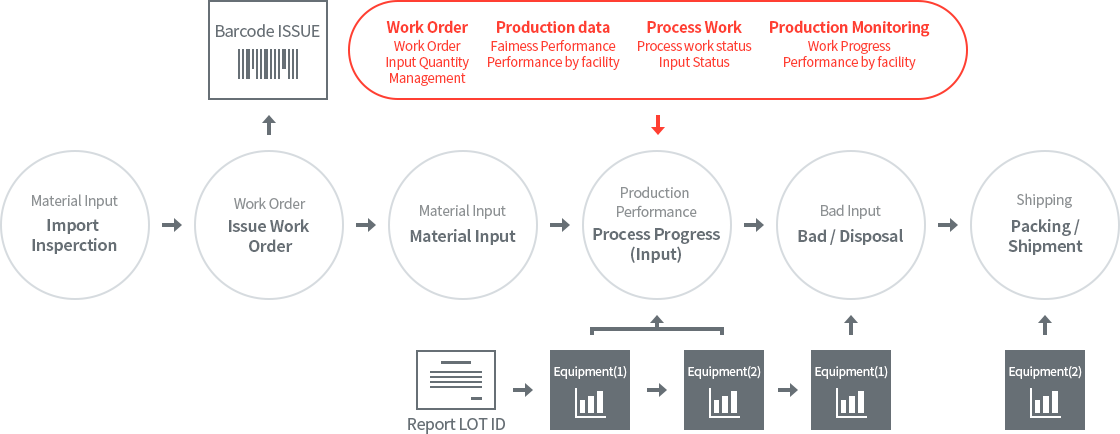

SMART FACTORY PLATFORM (MES/POP)

(Manufacturing Execution System / Point Of Production)

System Overview

The smart factory integrates all production processes such as product planning / Design, Production, Distribution / Dales with ICT technology, and produces custom products for customers with minimum cost and time. In addition, all the elements in the factory are organically connected, and the factory is capable of optimized production operation through various information services. GMIN MES / POP is a system that collects and analyzes valuable real-time information in real time so that production is performed according to a plan in a manufacturing execution system, and helps workers and managers make quick decisions.

System Configuration [14 Modules / 64 Functions]

| 기준정보관리 | 시스템 관리 | 영업 관리 | 품목 관리 | 수불 관리 | 재고 관리 | 생산 관리 |

|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

| 금형 관리 | 현황 모니터링 | 설비 모니터링 | Mobile POP | 품질 문서 | 품질 관리 | 전자 시스템 |

|

|

|

|

|

|

|

Introduction Effect

The construction of a process management system automatically and immediately reflects all conditions at the production site, thereby improving productivity and quality, and improving management levels from a management perspective. Decisions can be made.

| Operational effect | Managerial effect |

|---|---|

|

|

Manufacturing Process Innovation KNow-How Transfer Solution (NTS)

11 Kinds NTS Main Function

| 1Project management | It registers the production process and the work to be analyzed by project and creates and provides the work and files corresponding to the project. |

|---|---|

| 2Project Analysis Registration | Click the project, register the work, and provide the function to save the work and video files corresponding to the project. |

| 3Work analysis | It provides the function to measure the time by giving the stop position to the image file for each period such as preparation operation, basic operation, finishing operation, exception operation, and waste operation of the task. |

| 4Process improvement | After analyzing the selected work, it provides the function to register and improve to make the improvement of the analyzed work. |

| 5Comparative Analysis/Registration | In order to observe the difference by worker's characteristics or machine's characteristics, it provides the function to register and save the image file of the analysis of the work. |

| 6Comparative Analysis/Analysis | It provides the function to observe the difference by the same characteristics by worker or by machine. |

| 7Human+Machine Federation | Provides the ability to register and analyze the association work between people and facilities. |

| 8Multiple Analysis | It provides the function of registering and analyzing to combine and analyze the work actions of the line. |

| 9Line Balancing | It provides the function of registration and analysis in order to analyze the combination of several work movements of the production line. |

| 10Graph | Provides working graph of analysis, comparative graph of comparative analysis, project graph, etc. |

| 11Report | Provides the ability to convert each analyzed data into an Excel report. |

NTS Process

- Recognition of Need for Process Improvement

- Recognizing Problems in the Process

- Fair improvement theme selection

- Movie shooting

- Create 7 Waste Time Tables by Action

- Union Work Analysis

- Determination of Waste Elimination

- Improvement Modeling

- Design reviews

- Before / After line balance analysis

- Process design

- Layout design

- Create work guide

- Process layout

- share

- Waste removal

- Increased productivity

NTS MERIT

| MERIT1Optimal Standard Work | Operation for optimal standard work |

|---|---|

| MERIT2Work Order Process Improvement | Effective process improvement with standardized work order |

| MERIT3Standard video | Create a standard video to watch and learn |

| MERIT4System and Standardization | Standardization of systems and workers by job analysis |

| MERIT5Production site improvement | Eliminate and improve waste at production sites |

| MERIT6Productivity Improvement | Increase manufacturing productivity with analysis data |

| MERIT7Cost Savings | Cost reduction through manpower control |

| MERIT8Reduce delivery date | Shorter delivery due to detailed analysis |

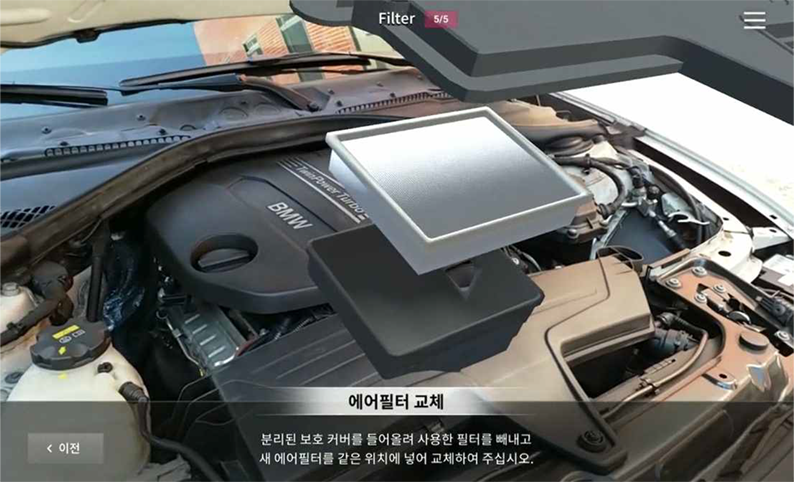

Remote AR

AR remote support solution linking office and industrial sites Complex and diversified industrial issues!

Distance, time and cost constraints to respond in the traditional way, such as by telephone, mail or dispatch.Communication via AR Remote Support!

Remote experts and field workers share situations and knowledge to solve

problems quickly and accurately.

| Before | After |

|---|---|

|

|

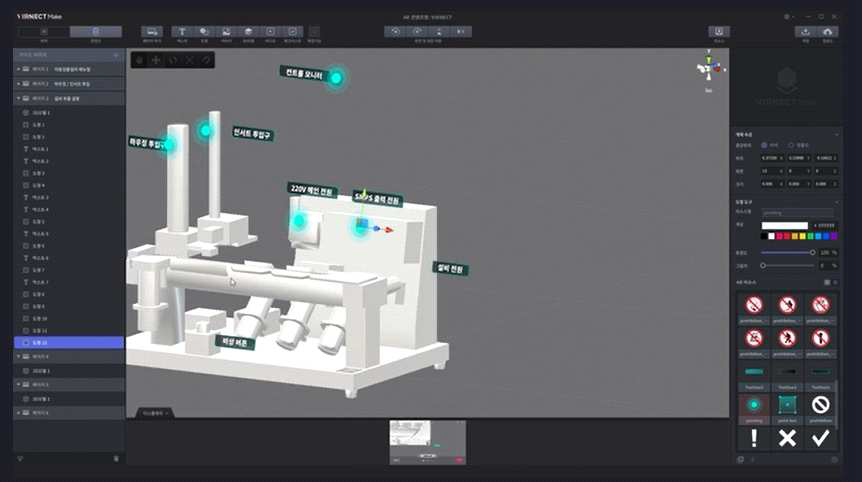

Make AR

Industrial AR content unfolds in front of you!

Innovate yourself with Make! Create AR content with information you need to see in the industry. Without time and space constraints and information security concerns, industrial sites will be filled with the information they need.

| Existing Industry Site | AR application at industrial sites |

In-house production of industrial AR content |

|---|---|---|

|

Conventional manuals are less efficient and

difficult to update information.

|

You can quickly and easily see

information in the field in a different way.

|

Producing your own AR content saves

production costs and reduces production time, Easy to maintain

|

View

Work in the field is easier. Operational information such as IoT sensor data and SCADA data can be visualized and checked in AR directly on the facility.

- Recognizing the markers of industrial sites through smartphones, tablet PCs, and smart glasses, facility information and related operational information are augmented and spread in front of the operator's eyes.

- By checking various important data in real time in the field, we can intuitively identify problems and make correct decisions.